Many times we have wondered how fabrics are manufactured with those who make up the clothes we wear or decorate with our house.

To better understand the process, first of all we are going to talk about textile fibres, which are the fundamental units from which the different textile products are made.

We can classify textile fibres into two large families:

Natural Fibers

As its name suggests, natural fibres are obtained from nature, and have an animal, vegetable or mineral origin.

| ANIMAL ORIGIN | VEGETABLE ORIGIN | MINERAL ORIGIN |

| Lana, Seda, Pelo, Cachemira, Mohair, Alpaca, Camello | Algodón, Lino, Yute, Esparto, Cáñamo | Glass, Metallic Fibers |

Chemical Fibers

Chemical fibres can be artificial, obtained by transforming the cellulose of trees, or synthetic, obtained by synthesising different petroleum derivatives.

| MAN-MADE FIBRES | SYNTHETIC FIBRES |

| Viscosa, Lyocell, Alginato, Acetato de celulosa | Poliéster, Poliamida, Fibra de carbono, Acrílicas, Elastómeros |

WHAT ARE THE MOST IMPORTANT CHARACTERISTICS OF ALL THESE FIBRES?

All fibres, both natural and chemical, have characteristics that will determine what the final product will look like. The most important ones are:

- Abrasion resistance: ability to withstand daily rubbing.

- Pilling: formation of knots or balls on the surface of the fabric by daily use.

- Brightness: intensity with which light is reflected in the fabric.

- Elasticity: ease with which a fabric returns to its initial length after having stretched it.

- Water absorption: capacity to absorb water. This characteristic directly influences the comfort of the product. garment. The higher the absorption rate, the greater the comfort.

- Action of light: effects that the sun’s rays have on the fabric (yellowing, resistance to breakage, resistance to abrasion…)

- Brightness: The intensity with which the light is reflected in the light. surface of the fiber. The structure of the fibre has a great influence on this. (the more round the fiber, the more light it will reflect).

- Fineness and length: these parameters to determine the softness of the fabric or its resistance to tearing.

- Colour: the natural colour of the fibres influences their ability to dye, print and discolour.

Depending on their origin, the fibres have particular characteristics, which will determine their different uses.

The most used natural fibers are:

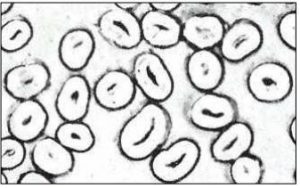

COTTON

Cotton is the most important and widely used natural fibre, obtained from the seeds of a group of plants of the genus gossypium. Cotton fibers do not mature all at once, so once harvested, they will have different length, different maturity and different fineness. In order to homogenize these differences, cotton can be mercerized so that it shines brighter, absorbs humidity better and dyes itself without difficulty. In addition, thanks to this process, in which the fibres are treated with caustic soda, they swell and soften, also increasing resistance.

Cotton fibers are used alone or mixed with fibers of chemical origin, to give them different uses.

How does he behave in the face of the flame?

Cotton burns easily, however, a flame retardant treatment can be performed to retard the flame.

JUTE

Jute is extracted from the stems of the jute, which reach to three meters high. It is the most widely used fibre of vegetable origin. after cotton. Being a cellulose fiber its properties are similar to cotton. This type of fiber is used for sacks, ropes, packaging or decoration and accessories.

The main disadvantage of jute is its brown colour, which normally dyes darker colours.

LINEN

Flax fibres are extracted from the family of plants called “linaceae”. Flax is rarely used today for textile products, due to its high cost of production. A characteristic of flax is that it wrinkles easily, so it is often mixed with chemical fibers to improve ironing.

WOOL

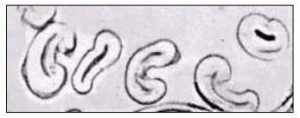

Wool is an exceptional fibre obtained from the coat of sheep and goats. rams through manual or robotic shearing. Once the the wool is classified according to the qualities of the wool. animal. After these operations, the wool obtained is washed, due to the large amount of dirt on these fibers.

The main characteristic of this fibre is its excellent thermal insulation, which is why it is used in winter fabrics. It is also a good heat conductor and absorbs up to 35% of its weight in water, without feeling wet.

The biggest drawback of wool is its tendency to suffocation (shrinkage) which increases with mechanical washing and high temperature water. In order for the wool not to shrink, it must undergo certain treatments.

SILK

The silk comes from the Bombix Mori worm (silkworm) whose fiber, called fibroin is the only continuous natural fibre. These worms feed on leaves of mulberry. The silk production cycle begins one month after the the birth of the worms, which begin to make cocoons, for the become a chrysalis and then a butterfly.

Silk is characterized by its fineness (from 10 to 20 microns) and shine, and is intended for clothing and tapestries

FIBERGLASS

This fiber is obtained by the fusion of different glasses and its main characteristic is the ability to withstand high temperatures. In addition, it is non-flammable and non-flammable.

SILICON FIBER

They are characterized by maintaining their characteristics at temperatures up to 1000 º C.

The most commonly used artificial fibres are:

ALGINATES: fibers derived from algae, used for bandages and textiles for wound care in general.

RAYON VISCOSA : cellulose derived fibers from wood (mainly eucalyptus, for the large amount it generates and for its rapid growth). Its main characteristic is its capacity to shrink after washing.

MODAL : regenerated cellulose fibres obtained from cellulose of a higher quality than that used for viscose rayon, making it more resistant than viscose rayon.

As for the chemical fibers that are most used we highlight:

POLYESTER : synthetic chemical fibre made from a synthetic polymer extracted from petroleum.

We emphasize its low moisture absorption, which moves to little breathability and easy drying. It is also characterized by a high pilling formation, which can be minimized with treatments such as the ensosado, which weakens the fibers and allows the balls to break.

ELASTAN FIBERS : Obtained from polyesters that are made to react with substances to obtain a result of flexible threads. They are used for clothing such as bathing suits or corsetry, covers or orthopaedic fabrics.

All fibres, whatever their origin, can be characterised as follows function of length, fineness and tensile strength.

How can we identify a fiber based on its behavior in the face of a flame? If it burns with a live flame and smells of burnt paper, it is a cellulose fiber; if the flame is self-extinguishing and smells of burnt horn, it is a protein fiber; if we observe that the residue is a hard ball that smells of burnt plastic, the fiber we are burning is synthetic.

What are the abbreviations for the most commonly used textile fibres?

| AR | Aramides | PES | Polyester | |

| AS | Antistatic fiber | PP | Polypropylene | |

| CA | Acetate, or Rayon Acetate | PU | Polyurethane | |

| CO | Cotton | PVC | Polyvinyl Chloride | |

| CV | Viscose or Viscose Rayon | RA | Ramie | |

| EA | Elastane | RES | Acrylic resin | |

| GL | Fiberglass | SE | Silk | |

| JU | Jute | SI | Sisal | |

| LI | Linen | SIL | Silica | |

| PA | Polyamide – Nylon | SILCN | Silicone | |

| PE | Silicone | WO | Wool |