As a consequence of the advance of modern technology in all branches of production, in particular in the textile industry, the control of materials is more and more indispensable, from the reception of the raw material to the output of the yarn or fabric as a final product.

| SPECIFIC PROPERTIES |

| Control de calidad de las propiedades geométricas Control de calidad de las propiedades mecánicas Control de calidad de propiedades retentivas |

Quality control of geometric properties:

1.- Grammage

The weight of the fabric is one of the most important fabric parameters. The weight is used to check the correct performance of the fabrics, as it determines the amount of material used in their manufacture. It is expressed in grams per square metre, and can also be transformed into weight per linear metre.

The test that determines the weight is very simple to perform with a balance and a specimen cutter. The specimen is cut in a circular shape, corresponding to a square measuring 10 x 10 centimetres. Once cut, the specimen is weighed directly on the balance. The data obtained must be multiplied by 100 to obtain the weight per square metre. According to the UNE 12127 standard.

2.- Tissue density

The measurement of fabric density refers to the yarns and passes that the fabric has per centimeter. The measurement is carried out by direct observation and counting of threads and paces contained in a centimetre in the fretwork fabrics. The yarn counter is the device used, which fulfills two missions, that of increasing the vision by its magnifying effect and delimiting a determined length.

3.- Ligaments

The ligament is defined as the order in which the warp and weft threads are interwoven in openwork fabrics. Checking the weave’s ligament is important to control the correct performance of the weaving process. It is checked by direct observation of the sample. The device used is the yarn counter as a magnifying glass. The test standards are UNE 40017 and UNE 40161

4.- Dimensional stability

In the case of fabrics and garments where the dimensions must be stable, especially when washing, it is advisable to carry out a simple test check on a common washing machine.

This test can also be carried out in a more controlled way, by specific rules. The washing machine is tested according to the is called the Wascator.

In a simple way it would be enough to mark a length, fifty centimetres, in either the warp or the weft direction or transverse. Subsequently, a wash at 40ºC and a program of normal wash. The sample is then air-dried after which is remeasuring the lengths of the marks made.

The result, expressed as a hundred, gives us a real idea of the dimensional stability of this fabric. (3% maximum)

5.- Fabric deformation and distortion

The UNE 40.079 standard describes the methods for determining possible distortions between the two sets of threads, warp and weft, which make up the fabric and which must form a right angle to each other.

Such distortions, which may affect the presentation and appearance of the fabric, are considered definable in these possibilities:

- “Warp or Weft Arching”: When one or the other is not arranged in a straight line, such distortions, which may affect the presentation and appearance of the fabric, are considered definable in these possibilities:

- “Double bowing”: When the fabric has a weft bowing in such a way that the direction of the bowing is opposite between some areas of the fabric and others.

- “Bias”: When the warp and weft are not arranged at right angles.

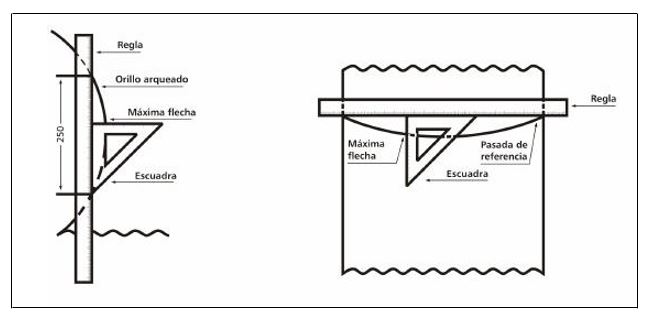

In these cases, on the sample or part previously conditioned for at least 24 hours in the normal test atmosphere, the maximum amplitude of the deformation is determined by means of a ruler and square graduated in centimetres and millimetres.

Figure 1 shows the operating procedure for measuring the arched warp, as the greatest perpendicular distance between the straight line that joins two points 250mm apart from the selvedge of the fabric.

Similarly, to measure the greatest perpendicular distance between the line that joins the two ends of an arched run and the most distant point of it, the graduated ruler (Figure.2) is placed across the fabric so that one of its edges cuts with the selvedges in conjunction with the determined run. Slide the square and check the maximum arrow of the mentioned run in relation to the ruler.

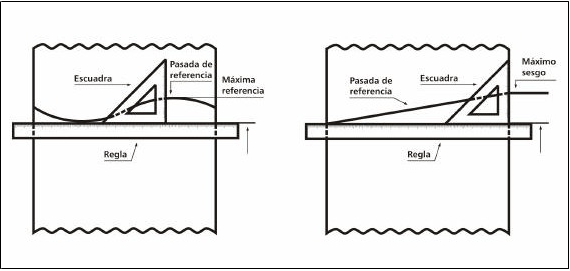

The double bow is measured as the smaller side of the rectangle capable of containing the passed Z, so that the other side of the rectangle is parallel to the line joining the two points where the pass cuts the selvedges. Figure .3

The bias is measured as the distance between the end of a pass and the point on the selvedge itself, intersected by a line from the other end of the pass and perpendicular to the warp (Figure 4) and expressed as a percentage of the width of the fabric.

Quality control of mechanical properties:

1.- Tensile strength

Tensile strength is the resistance of the fabric to breakage and is of particular importance in determining the use of that a fabric is intended. In the case of fabrics with applications, the knowledge of this value is decisive in the use of ideal of the fabric.

Another parameter that is analyzed in the realization of this test is the increase in length when a tensile force is applied, in definitive elongation of the tissue.

The resistance can be measured both in the fabric, in the sewing, in the case of clothing, and in the tearing.

The equipment used is the DYNAMOMETER, basically a pair of tweezers, one is fixed and the other is mobile, the latter being responsible for making the necessary effort to produce the breakage of the fabric.

2.- Wrinkle resistance

Wrinkles are small folds -more or less marked- that are distributed randomly over a textile surface, altering its smoothness.

They appear during tissue manipulation and in the use of garments, and are caused by pressure and bending stresses. At other times we may need a permanent wrinkle and therefore not will help to know the tissue that will behave best.

Crinkle analysis is used to check the ability of a fabric to regain its original shape after being subjected to a load.

The norm to follow is the UNE-EN 22313:1993 Textile fabrics.

3.- Resistance to fabric snagging

In order to check the resistance of the fabrics to snagging, we make this test, which is described in the ASTM 3939.

Specially designed for knitwear. The textile article covers the cylinder, which can be clearly seen in the photograph, and takes contact with the spiked ball. The turning movement of the cylinder, each full turn is called a cycle, which has contact with the ball produces the hooks.

After the time described in the standard, the resistance is evaluated by direct observation and comparison with standard photography.

The score ranges from 1 to 5, with 5 being the strongest.

Quality control of retention properties:

1.- Solidities:

Lightfastness: this is the name we give to the resistance to light modification of a dye due to the effects of daylight. The most commonly used device is the Xenotest. The test is carried out according to the UNE-EN-ISO 105 B02 2001 standard, in which the performance, equipment and conditions of the test are indicated. The assessment will be done visually by more than one person, who will compare the degradation suffered by the dye and that of the blue. Rating from 1 to 8.

– Washing strength: with this test we designate the resistance to modification of the colour of a material subjected to washing. The apparatus used for this type of test is the Linitest which consists of a container with water to act as a water bath. The test follows the procedure described in the UNE-EN-ISO 105 C06 1997 standard. An ECE standardised detergent is used.

– Rubbing strength: this name designates the resistance to modification of a dye that is subject to the effects of rubbing. The apparatus used for this type of test is the Crockmeter. The test is determined by the UNE-EN-ISO X12 2003 standard.

– Rub fastness to organic solvents: this test is performed as well as the solidity to the rubbing but wetting the witness with solvent.

– Ironing strength: this is the name given to the resistance of the dyeing of textiles of any nature and in all its states of transformation to current or treatment ironing industrials on hot cylinders. The test follows the standard applied UNE-EN ISO 105-X11:1997. The apparatus used for this type of test is the Fixotest.

– Water fastness: the fastness of water-based dyes is valued immersion in water, in textiles of any nature and in the state of transformation, by means of white witnesses. The test follows the UNE-EN-ISO 105 EO1 1996 standard. The instrument used is the Pespirometter.

– Fastness to sweat: the fastness of the dyes in the textiles to the action of sweat produced by the human body. The Pespirometter is used for the test. The test follows the standard UNE-EN ISO 105-E04:1996.

– Fastness to bleaching with hypochlorite: the strength of dyes in textiles to the action of bleach. Standard used UNE-EN 20.105-N01:1996.

– Fastness to dry cleaning: the fastness of the dyes in the textiles to the action of perchloroethylene is valued. The test follows the UNE-EN-ISO 105 D01 1996 standard. The sample is analysed inside a bag made of standard cotton fabric.

LIGHT BOX

The light box is the place where all solidity assessments should be performed, placing the samples horizontally on a white or neutral background and with the required standard illuminant, normally the D65 daylight illuminant is used.

ABRASION RESISTANCE

Abrasion resistance is based on two fundamental principles: the first corresponds to the number of cycles required to produce the and the second in the calculation of the average loss rate of tissue mass.

The methodology is mainly based on the determination of the number of cycles required to break two wires in the case of a fabric intended for decoration and three threads for fabrics intended upholstery.

To determine the abrasion resistance of fabrics, it is usually use the UNE-EN ISO-12.947 standard, which specifies all the parameters necessary to carry out the test,

as well as the materials and apparatus required to carry out the test.

Of all the uses to which a fabric may be subjected, the resistance to abrasion

is usually much more important than its tensile strength. A in this respect it can be said that the ligament or texture plays a role important.

The test conditions also influence the result, considering the type of abrasive surface, the pressure on the fabric, the stress it is subjected to, etc.

The abrasion resistance determined in a laboratory is one of the most important factors

contributes to the prediction of the behaviour of a tissue in its subsequent use.

Device used to carry out tests:

PILLING RESISTANCE

The so-called “pilling” effect is a phenomenon that has been known for time in the textile field. It is presented in the textiles composed by fibres, especially if these articles contain synthetic fibres.

Pilling manifests itself on the surface of fabrics in the form of small balls of variable dimensions produced as a result of the physical-mechanical process to which the manufactured garments are subjected during use, especially as a result of friction from certain areas of the fabric with itself and/or with other elements external. These fiber mixtures are retained in the textile by other anchorage fibres, giving the fabric an unpleasant appearance that is the first sign of aging and wear of the garment.

Finishing and sizing operations that reduce the tendency to pilling

- Thermofixing: This process fixes the position and torsion of the fibers, preventing them from sticking out of the assembly.

- Singeing: This operation removes theends of the fibres on the surface of the fabric. In the case of chemical fibres, it should be borne in mind that their molten ends absorb a greater amount of dye than the rest of the fibre and are stain, therefore with a more intense tone. The singeing operation should generally be carried out after dyeing, with the exception of when the litmus procedure is used.

- Hot calendering: Produces a compacted crush and a smoothing of the tissue surface, as well as a fixation of the fibres, reducing their migration to the surface of the fabric.

- Shearing: There are several treatments,

- Resins that imprison the fibres, preventing their migration to the surface of the fabric

- Silicones that reduce the abrasion of the surface of the fabric, delaying the formation of pellets.

Tests: the most widely used is UNE-EN-ISO 12945-2

It is done with the Martindale Abrasimeter.

The valuation table when determining the degree of pilling of fabrics, will be common for all regulations, whatever the test method to be used:

5 – NO VISUAL CHANGE

4 – SUPERFICIAL HAIR AND AN OCCASIONAL PILE

3 – MODERATE PILLING FORMATION

2 – VISIBLE AND ABUNDANT PILLING

1 – VERY INTENSE PILLING ON ALL SURFACES

AIR AND WATER TIGHTNESS

The air tightness is measured in the air permeability meter according to the UNE-EN 9237 standard. This device measures the amount of air that is able to pass through the fabric.

The measurement of waterproofing follows the process of the UNE-EN 20811 standard the test apparatus, water permeability meter.

It measures the amount of water that the fabric supports until the appearance of the third drop, the result is expressed in mm.

WATER REPELLENCY OF FABRICS

The determination of a fabric’s capacity to repel water is measured with the Sprau-test, according to UNE-EN 24920 and the result is expressed by comparison with Standard.

BREATHABILITY

The behavior of certain tissues preventing the passage of water and allowing our perspiration to pass through, in the form of vapour, is a desirable effect for certain tissues. This feature increases the feeling of comfort. Waterproofing / breathability takes advantage of the difference in the size of the water in its different states of liquid and vapour.

The water vapour resistance test is based on the which offers the fabric to the passage of water vapour produced in the team’s dish. The test is carried out according to UNE EN 31092 equivalent to ISO 11092

MEASUREMENT OF THERMAL INSULATION CAPACITY

Due to market requirements, new tests are appearing all the time in order to predict as objectively as possible the behaviour of products in real situations. This is the objective of that trial.

EFFECTIVENESS OF OIL AND WATER REPELLENT SIZING

This test aims to determine the behaviour of the tissue against liquid, possible sources of staining. Many tissues have the water-repellent or water-repellent properties of different oleophobic agents (oil repellency) but other tissues that do not initially presented, they can acquire it with different parting of the tissues. This is an application of products fluorocarbons that delay the penetration of water and grease by fabric.

- Determination of water repellency. 3M Test II method. The value of water repellency of the tissue, it is the test fluid of number more something, which does not wet the tissue in a period of 10 seconds, (the Test liquids used are water and alcohol mixed in different proportions), obtaining a high number indicates a greater repellency.

- Determination of oil-repellency. Standard: AATCC 118:1984 The AATCC value oil-repellent fabric, is the test fluid of number which does not wet the tissue within 30 seconds, (the Test liquids used are hydrocarbons of different weight molecular).

ANTIBACTERIAL COATING

Through ISO 20743:2007 This international standard specifies quantitative test methods to determine the activity antibacterial in finished textile products including nonwovens, arranged in a nutrient medium inoculated with the microorganism selected, to the growth of the selected microorganisms.

MEASUREMENT OF THE RESISTANCE OF LAMINATES AND BENDS

By means of dynamometry, the cohesion of a material can be examined susceptible to being rolled, under well-defined conditions. It is studies the strength of adhesion between different layers of tissue or between the fabric and the different layers of other materials such as foamed foam.

U.V. LIGHTNING RESISTANCE

There are different standards that determine the degree of protection of the fabric against UV rays.

The most complete and the one that also offers protection results after having subjected the textile article to a life time (washing, dry cleaning, abrasion, light…) is : UV-Standard 801-1998. Ultraviolet label.

FIRE RESISTANCE

Current reaction to fire tests focus on reproducing the most accurate possible way the actual conditions of use and evaluate the most critical parameters of the product in question to guarantee in the highest possible degree of safety in the event of a fire.

The following parameters to be measured can be distinguished:

- FLAMMABILITY OR EASE OF IGNITION

- FLAME PROPAGATION

- DROPLET OR PARTICLE SHEDDING

- HEAT OUTPUT

- SMOKE PRODUCTION

AGEING IN CLIMATIC CHAMBERS

The behavior of the articles is studied (stability dimensional, color changes, brightness…) when subjected to different temperature and humidity cycles in specific chambers, following manufacturers’ regulations.

TOUCH

The Kawabata Evaluation System, KES is a system that allows you to detect quantitatively and objectively the feel of a tissue from the analysis of a set of physical variables.

The following mechanical properties can be measured:

- Tension and Shear

- Bending or folding

- Compression

- Surface